CORONA IMAGING - SEE THE INVISIBLE

It felt like a fine spring morning in eastern Oregon as my colleague and I rolled up the power plant driveway, although the date on my Blackberry indicated mid-February. After some friendly greetings and hand-shaking with maintenance personnel, we signed in at the control room and viewed the not too lengthy or boring safety video. Then it was time to don our hard hats and head toward the substation – all half-million volts of it.

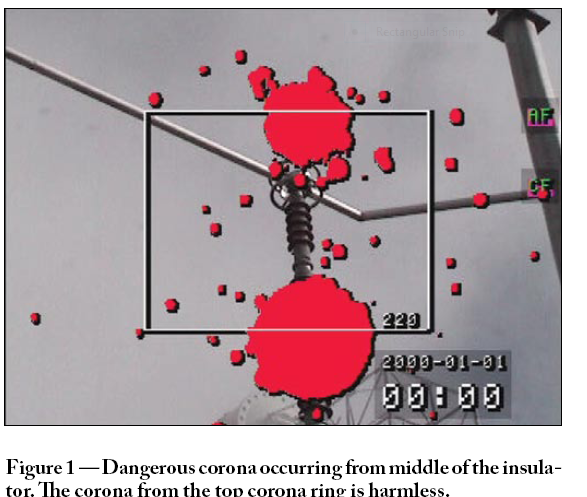

It was dry and sunny as our work boots crunched against the coarse substation gravel rocks. The massive bushings and insulators did not appear to have much, if any, condensation from the night before as we gazed across an acre of GSU transformers, SF6 dead-tank breakers and other equipment. Ideal conditions for a corona image survey. After powering up our new corona camera and making a few minor adjustments, we began doing what no other person had ever done before in this substation – we were viewing an invisible phenomenon known as corona. What we and plant personnel saw during the next few hours that morning would better our understanding of high voltage engineering in a manner that no text book possibly could. We saw corona from insulators that required cleaning, sharp edges from hardware connections, poor bus work corona suppression, and dangerous insulator corona caused by cooling tower residue deposits. As the prevailing wind puffed another cloud from the cooling tower onto the westernmost insulators, we could hear the corona crackling intensify as the camera revealed near flashover conditions. “When it sounds like this, I tell my guys to get out of the substation,” our customer stated. Not a bad idea, I thought. Next, we followed our customer to a corner of the substation were we examined a flash-damaged insulator laying in the gravel, then observed the additional weather sheds added recently to the in-service insulators nearest the cooling tower. For the most part, the increased surface creep age of the modified insulators were doing their job by eliminating most of the corona. However, as can be seen in Figure 1 one insulator was clearly showing dangerous corona that consistently occurred from a defect located half way down the insulator. Additionally, we found severe corona activity occurring from the center phase GSU transformer bushing as shown in Figure 2.

We left the power plant feeling that the customer greatly appreciated the value of our new technology and would use the knowledge gained that day to reduce future flashover likelihood. One of the greatest difficulties when working with electricity is that it cannot be seen. The technician must generally determine its presence based upon meter deflection or simple visual or audible warning signals. Perhaps even more difficult to appreciate is the concept of electrical fields surrounding conductors or insulators in air. A visual representation of the electrical field is shown in Figure 3.

which illustrates the voltage gradient surrounding an insulator. Medium- and high-voltage equipment is carefully designed so that electrical fields are contained. If the electrical field is compromised by foreign materials, poor design, or other factors, corona will occur. Corona is responsible for the generation of ultraviolet radiation, ozone, acids, heat, mechanical-erosion through ion bombardment, electric power loss, and electromagnetic interference of radio communications. Corona by-products destroy insulation and lead to catastrophic failure while remaining invisible to the eye.

Corona can occur due to:

poor component or system design

improper installation or workmanship

temporary contamination by icing, salt sprays near highways or oceans, fog, agricultural chemicals, and other chemicals

damage due to storm wind or lightening

damage due to vandalism

cumulative damage due to corona activity caused by weather conditions

cumulative damage due to contamination from nearby sources

Until recent technology breakthroughs, ultrasonic detection was one of the only methods capable for detecting corona. This technology is limited, especially when scanning high voltage equipment from a distance since only the relative direction of the problem source can be determined.

Today, a relatively new technology allows invisible corona to be visible through a special imaging device. The handheld camera seen in Figure 4.

clearly displays the ionized air created by harmful corona activity by indirectly detecting the associated ultraviolet radiation. The camera user can change the color of corona image to allow subsequent transfer of the image to a PC for report generation. This highly effective technology is quickly becoming an indispensable tool for the technician. In addition to the obvious maintenance applications for all types of medium- and high-voltage equipment, the corona camera can also be used for:

supplementing partial discharge and ultrasonic surveys

• acceptance testing of new or modified installations

• product quality assurance

• design verification

• field and shop high potential testing

• general research

We can now even have a much greater understanding of equipment insulator and conductor behavior when conducting routine high potential testing.

displays the absence of corona while performing an ac high potential test of a medium-voltage circuit breaker, indicating good insulator and conductor condition, while Figure 6.

shows unwanted corona generating from inadequate clearance of the energized test conductor during the same test. It is apparent that the breaker was good but our temporary shop test setup was not. The future use of corona imaging promises to provide many new applications and many associated new surprises, but one thing is certain — we will never think of corona in the same manner, for now we can see it.